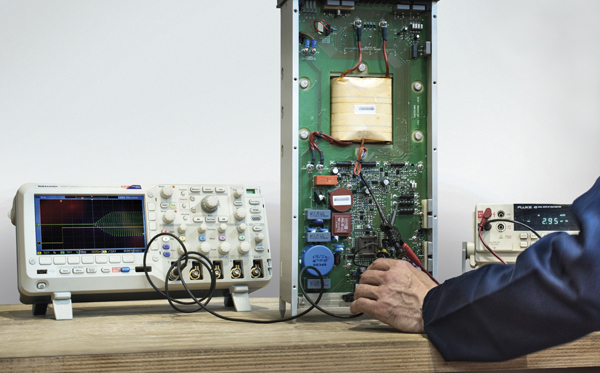

PROTOTYPING is considered by SECAP to be a fundamental step in project development and validation. To back up design engineering activities, the company has set up special departments engaged in producing the prototypes required for the complete execution of the electronic project, in terms of both mechanics/hardware and firmware/software, so as to actuate all inspections and the necessary improvements resulting from a comparative analysis of the technical specifications and thefunctional test results.

The prototypes are produced in full scale and their engineering feasibility is tested with a detailed series of application tests to verify electrical functionality in situations typical of an operative environment (temperature chamber), EMC pre-compliance tests and heat tests (heat chamber). The test results are sharedopenly with the customers, to demonstrate our commitment to act as authentic partners of the product development team