Specialized human resources and advanced technologies enable us to manage the in-house mechanical and electronic production and also special processing for external customers.

Having the team of developers and design engineers close to the production site allows for great flexibility, in both development and small-scale production activities; this aspect translates into a tangible advantage for the customer with regard to timing and production costs and, above all, in the successful conclusion of all SECAP projects.

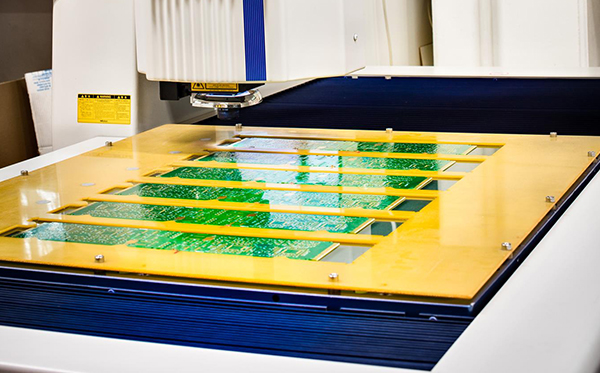

Manufacturing processes are based on projects of our own or those of our customers, using nothing but certified materials which are assembled in special departments with the necessary high level of cleanliness to guarantee the best possible results and quality certified from manufacturing processes

Manufacturing processes are based on projects of our own or those of our customers, using nothing but certified materials which are assembled in special departments with the necessary high level of cleanliness to guarantee the best possible results and quality certified from manufacturing processes

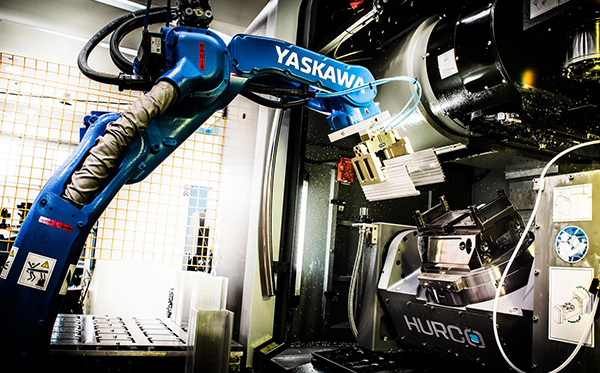

Our production plants extend over 6,000 sq m and principally consist of:

Our production plants extend over 6,000 sq m and principally consist of:

• 11 work hubs of 2 and 3 axes and robotized centres

• aluminium die casts using moulds of our own production

• sanding machines with computerized pantograph

• multi-spindle automatic lathes

• robotized washing-degreasing stations

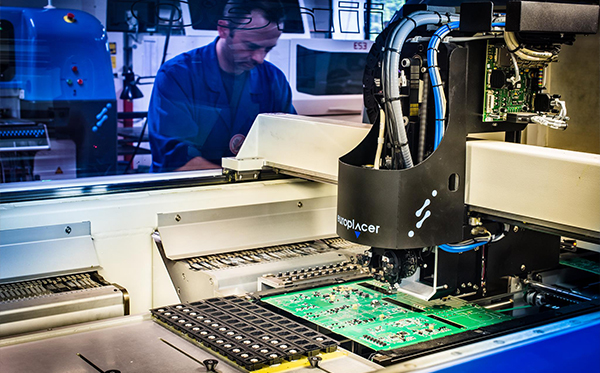

The electronic production floor uses special pick&place automated systems, remelting furnaces, selective soldering and vacuum vapour phase soldering.

The electronic production floor uses special pick&place automated systems, remelting furnaces, selective soldering and vacuum vapour phase soldering.

Special automatic machines for optical gauging (O.G.P.) and X-ray inspection, allowing for attentive and accurate inspections of solderings and positionings